Structural Control for Response Reduction

MR Dampers

The magnetorheological (MR) damper is a type of controllable fluid damper that can be applied to modify

the response of structures for improved performance and disaster resilience under extreme loading events.

The MR fluids inside the damper have the ability to reversibly change from a liquid to a semi-solid upon application of a

magnetic field, increasing the yield stress in the fluid, and generating forces in these devices that

are up to 50 times larger than without the field (see Blog

for more information on MR fluid).

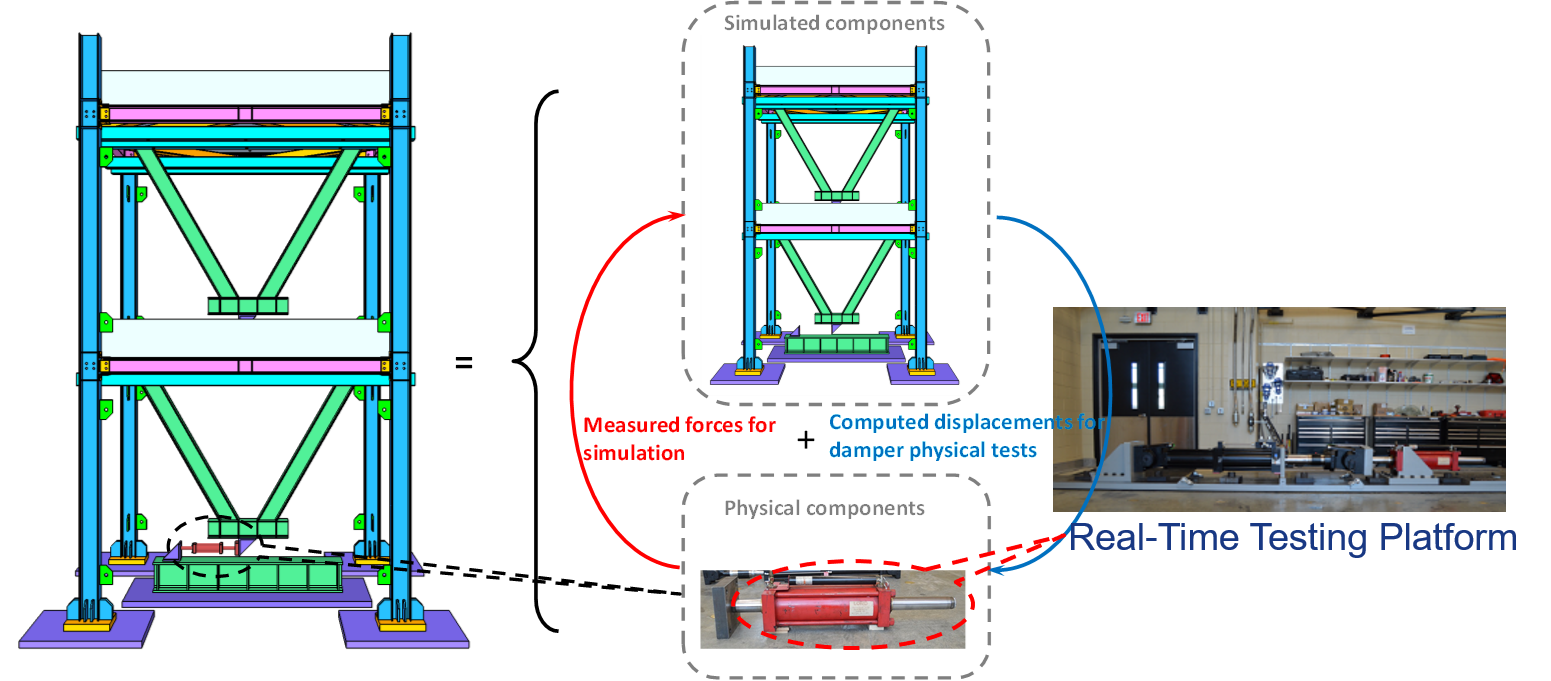

Both small- and large-scale MR damper testing platforms (see figures above) are currently available in the lab.

We are designing advanced MR damping systems with novel controllers to provide optimal response reduction effects. The developed

MR damping systems can be widely applied in structures subjected to random dynamic loading contions.

Mass Dampers

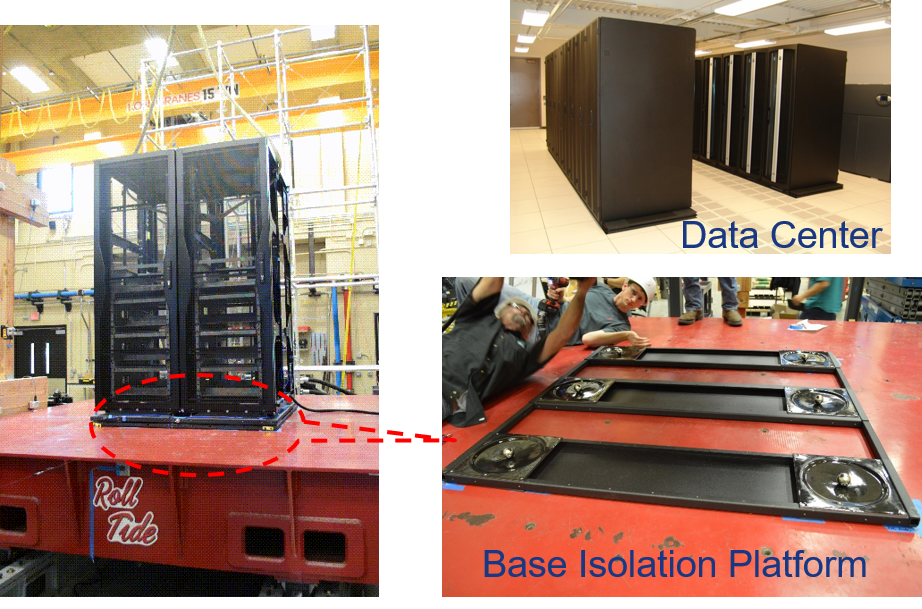

We are interested in developing novel damping devices and systems. The figures shown above is the shake table tests conducted on a special typed mass damper--disruptive mass damper (DTM).

Base Isolation Platform

The figures shown above is the shake table tests conducted on a multi-unit rolling isolation system (RIS). This type of isolation systems is used to isolate mission-critical equipment (server cabinet in this case) from earthquake-induced ground and floor motions.